Every industrially made paper has a paper grain direction. This grain direction stems from the way the pulp slurry is ejected from the headbox of the paper-making machine onto either a wire mesh or between two felts. The paper fibres orient themselves in the direction of the newly formed paper web travelling through the machine. The grain direction of a sheet of paper is expressed as being along the long or short side of the sheet. The papermaking process is described in the following video.

How to determine the grain direction of a sheet of paper can be determined using the so-called “Slump Test”. Two strips of paper are cut out from a piece of paper. One strip along the short side of the paper and the other along the long side of the paper. Both paper strips need to have the same width. Also when performing the Slump Test it is important that the same length of both paper strips are compared. The paper strip that shows more slump is grain short and the strip that shows less slump is grain long.

A micrometer measures paper calliper, its thickness in thousandths of an inch or fractions of a millimeter. Calliper is an important specification for ensuring that paper meets the minimum and maximum specifications of the press or printer. It also correlates with other measurements such as stiffness, folding endurance, and tensile strength.

| Reading | Thickness of 4 sheets (in.) | Thickness of 1 sheet (in.) |

| 1 | 0.0420 | 0.0105 |

| 2 | 0.0415 | 0.0104 |

| 3 | 0.0410 | 0.0103 |

| 4 | 0.0415 | 0.0104 |

| 5 | 0.0415 | 0.0104 |

| average | 0.0103 |

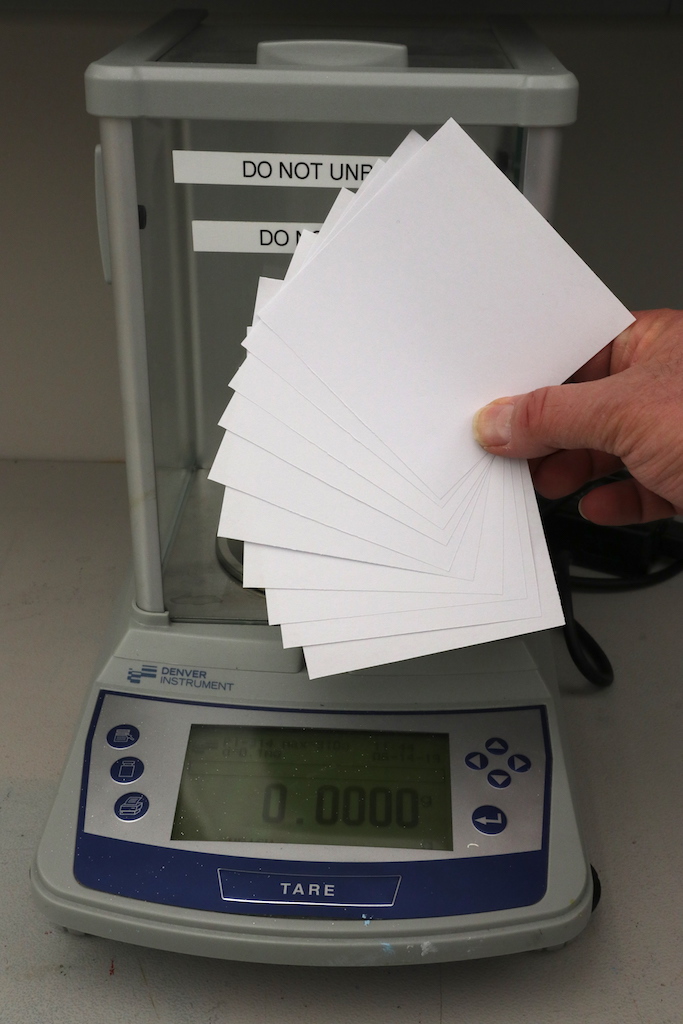

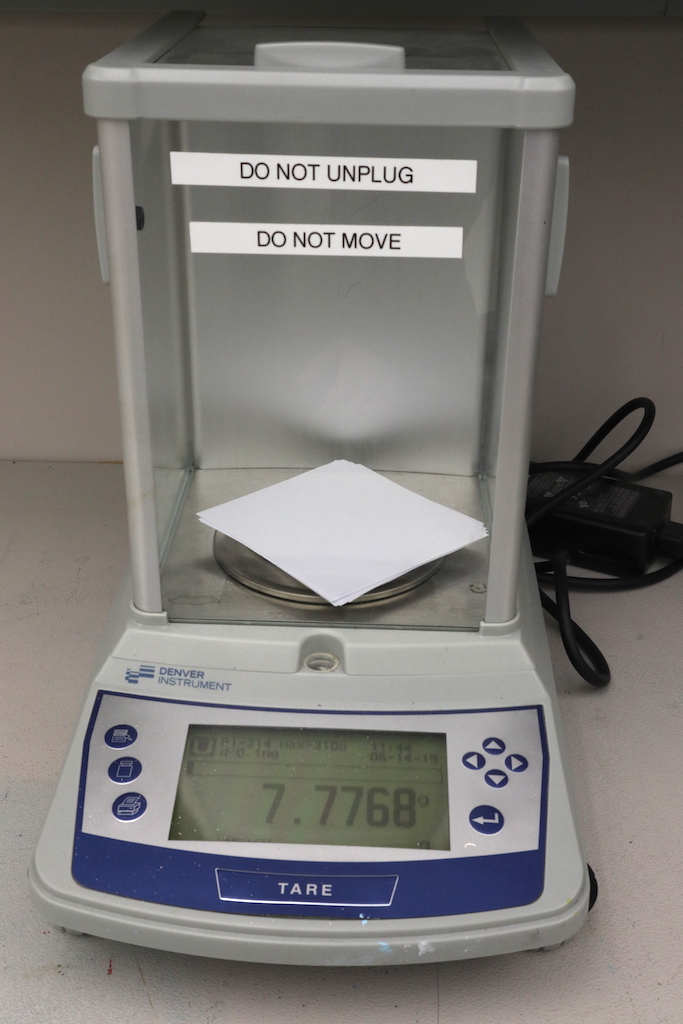

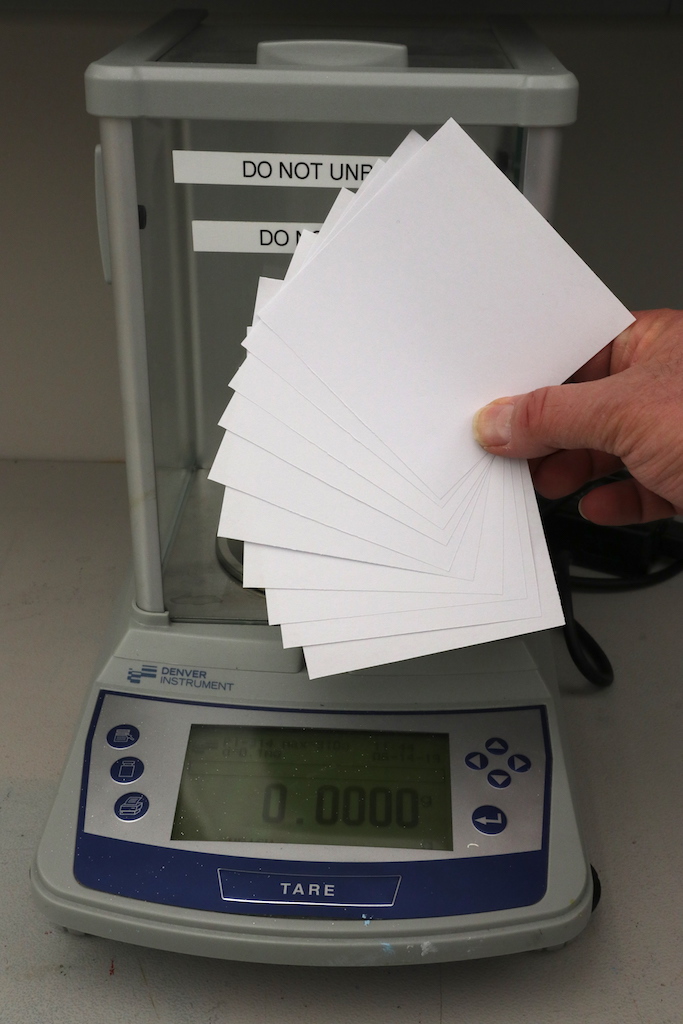

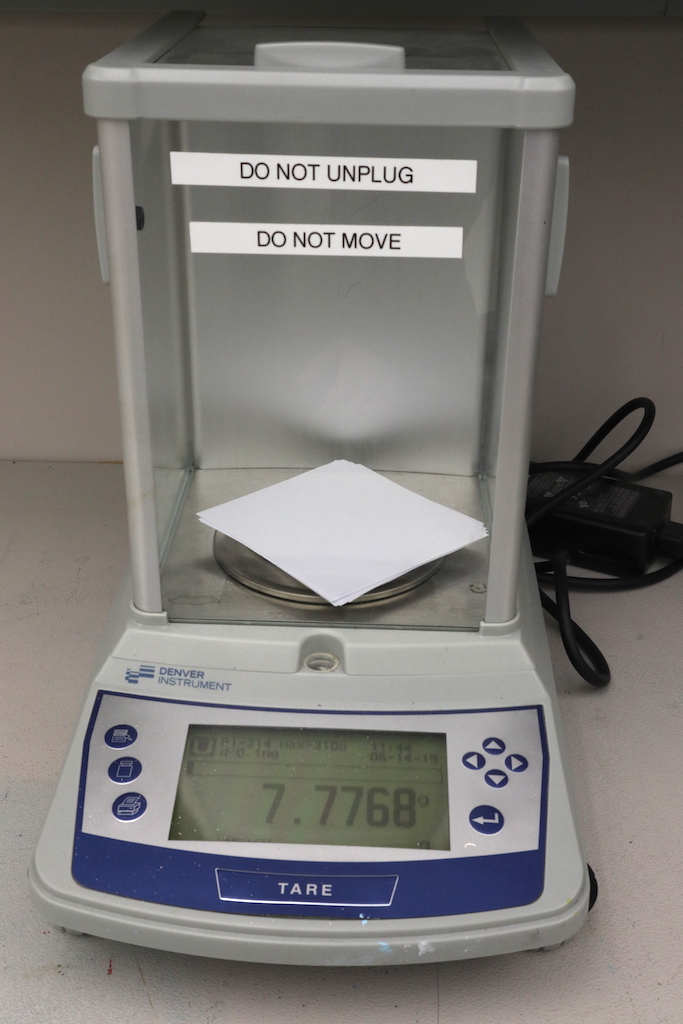

Three measurements used to quantify the weight of paper are M-weight and basis weight(imperial), and grammage(metric).

M-weight. Although office copier and laser printer paper is typically sold in packages of 500 sheets (a ream), a paper manufacturer or distributor may supply printing paper in packages of 1,000 sheets and in different sizes. The M-weight is the weight in pounds of 1000 sheets of a specified size and is indicated by a number and the letter “M,” e.g., newsprint 78M 28×40 in.

Basis weight. This is the weight in pounds of one ream (500 sheets) of paper at the specified basic size. For an “80-lb. bond” paper, 500 sheets of 17×22-in. paper would weigh 80 lbs. Basis weight can be written as “80#,” “80-lb.,” or “80-pound.”

| paper type | basic size (in.) |

| bond/writing | 17×22 |

| book/offset/text | 25×38 |

| cover | 20×26 |

| newsprint | 24×36 |

One problem with basis weight is that different paper types, e.g., offset and bond, can have different relative weights because their basic sizes are different. For example, a sheet of 8.5×11-in., 80-lb. bond weighs more than the same size of 80-lb. offset paper, because the basic size of the offset paper is bigger than that of the bond.

Grammage. The metric measurement of paperweight is measured in grams per square metre (g/m 2 ). Grammage expresses the weight of one square metre of a single sheet and thus does not refer to a ream or to a basic size. The measurement is uniform across all paper types.

|  |

You can calculate basis weight from M-weight and grammage from basis weight using the following formulas:

Equation 1. Basis weight from M-weight

basis weight = (M – weight × Area of Basic Size) ÷ (Area of M – weight paper × 2)

Equation 2. Grammage from Basis Weight

grammage = (basis weight × 1407.4) ÷ basic size

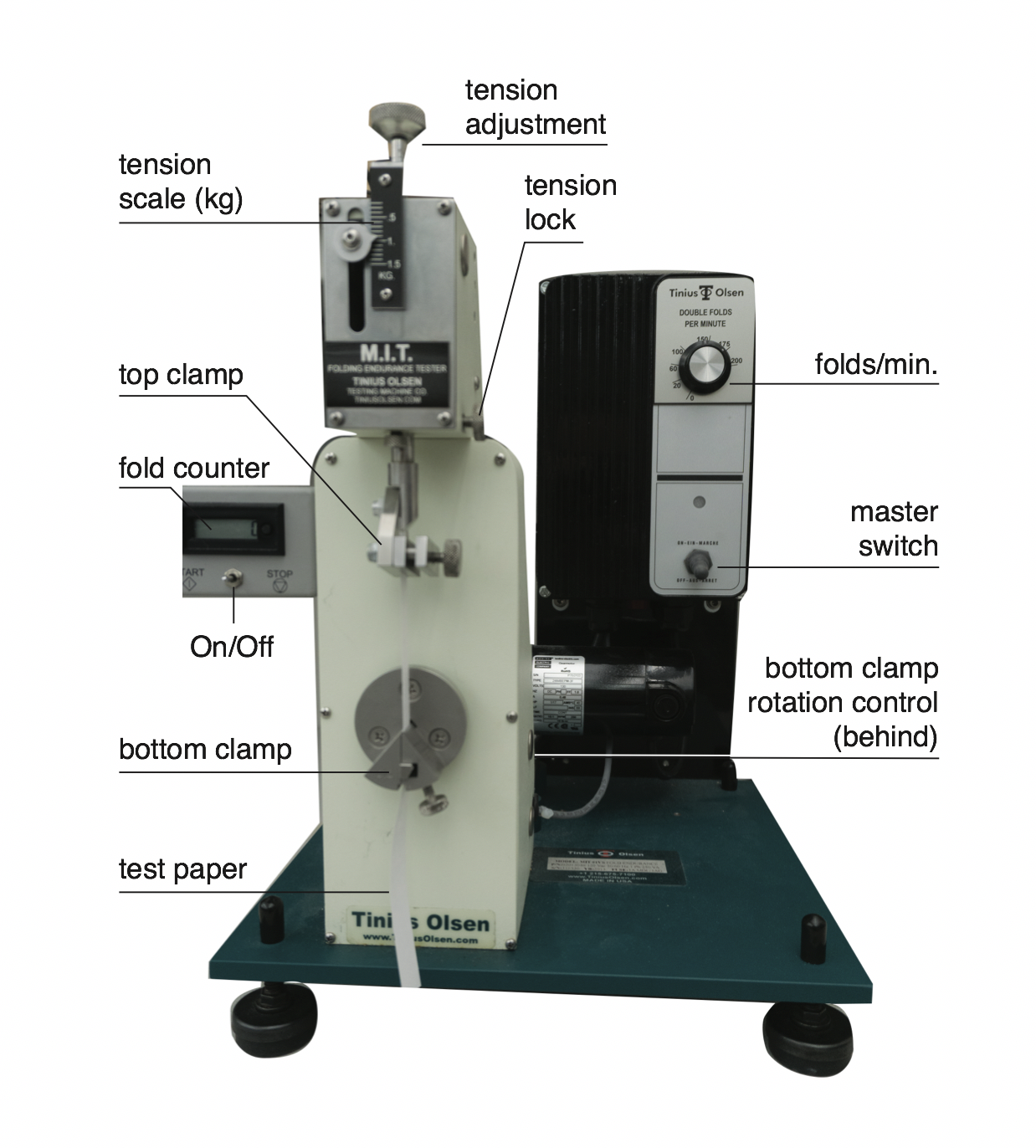

Folding endurance measures the number of folds required at a specified tension to break a strip of paper. Folding endurance is measured with the MIT Folding Endurance Tester.

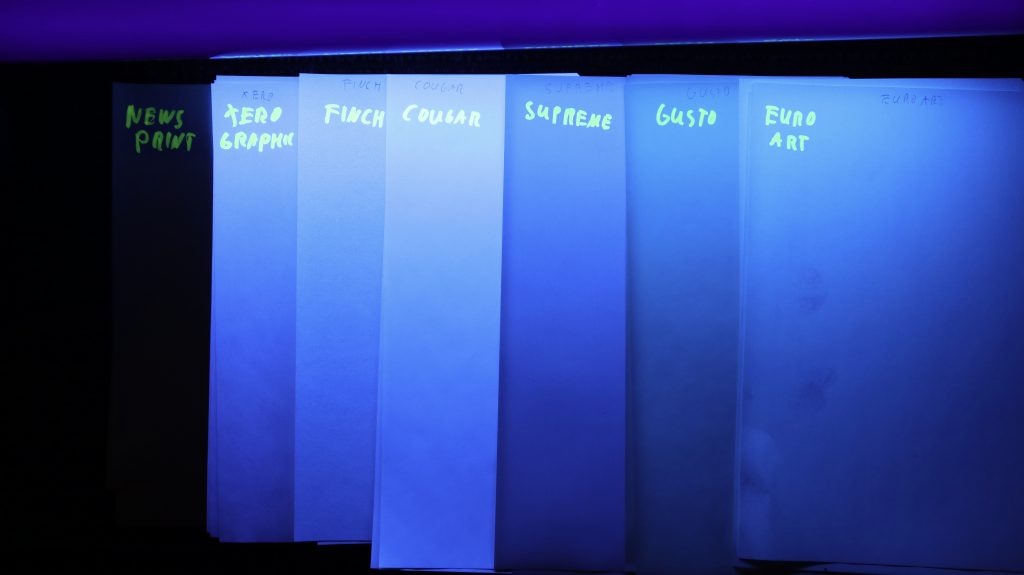

Paper brightness is a way of measuring the light reflected by paper. Brightness is associated with quality, especially the amount of cotton and bleached wood pulp fibres used in the papermaking process. Optical brightening agents (OBAs) can also be added to paper to increase its blue reflectance, so it appears less yellow. Brightness is measured as the reflectance of blue light at 457 nm wavelength, which is sometimes known as “R-457.” The brightness measurement procedure is specified by TAPPI Test Method T 452, thus the numbers 457 (wavelength) and 452 (number of the standard) can be confusing.

The brightness of pulp, paper, and paperboard (directional reflectance at 457 nm), Test Method T 452 om-08, retrieved from www.tappi.org.

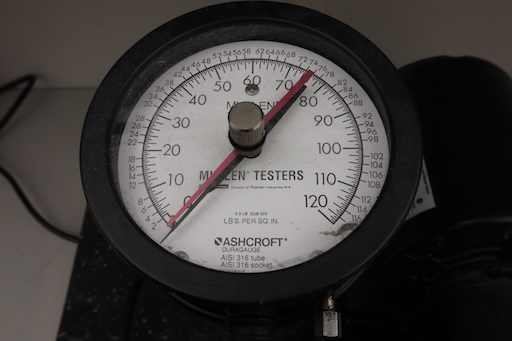

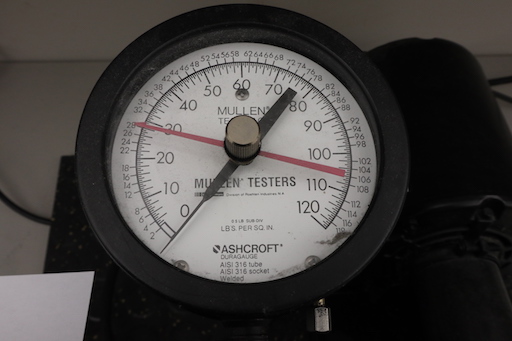

Bursting strength is measuring the resistance of a substrate to outside forces. According to Printwiki.org bursting strength is:” A property of paper or paperboard used in packaging that measures its resistance to rupturing, defined as the hydrostatic pressure needed to burst a paperboard sample when it is applied uniformly across its side. Bursting strength is a function of various processes performed in the papermaking process. The increased use of fillers [New Window] decreases bursting strength, while the increased use of longer fibres and surface sizing [New Window] increases a paper’s bursting strength.

Bursting strength is measured utilizing a rubber diaphragm that is expanded hydraulically against the paper sample. A bursting test is also known as a Mullen test [New Window] or pop test [New Window], and a minimum bursting strength is required for cartons used for shipping. Bursting strength has little application for printing papers.“

The official TAPPI test method is TAPPI/ANSI T403 om-15.

|  |

It is the elongation of the paper, which means, how much it can be stretched before it rips. The test is normally made to calculate the tensile strength in two different grains (long and short).

According to pulppapermill.com tensile strength of paper is:”

The tensile strength of paper is the maximum stress to break a strip of a paper sheet. It is one of the most important basic physical properties of paper and paperboard. The tensile strength is different based on the fibre direction. Since the fibre orientation is dissimilar between machine direction (MD) and cross direction CD), hence the tensile strength is measured in both directions. The machine direction is the direction of the paper web which is running on the machine whereas cross direction means the direction, which is perpendicular to the paper sheet that is running on the machine during papermaking. It is greater in the machine direction than in cross direction. It is calculated with the force per unit width and expressed as kN/m.

Tensile strength is used to find out how resistant paper is to a web break. The strength, length and bonding of fibres, the degree of fibre refining and the direction of the fibre are the main sources of the tensile strength of paper. It also depends on the quality and quantity of the fillers used. It is a significant factor for many applications like printing, converter and packaging papers.”

The official TAPPI test method for tensile strength is TAPPI/ANSI T494 om-01.

According to the TAPPI/ANSI T494 om-01, you can calculate tensile strength using the following formulas:

The tensile strength defined above as the breaking force (load) per standard width of specimen cannot directly explain the material properties of paper such as the inherent strength of a particular paper grade. This is because the tensile strength of paper defined as the breaking force (load) per standard width depends on grammage of the paper. For example, the tensile strength will be greater for paper of higher basis grammage.

Therefore, the tensile index is used to measure and compare the inherent strength of different types of paper grades. The tensile index is obtained by dividing the tensile strength in N/m by grammage ( g/m 2 ).

You can calculate tensile index from tensile strength and grammage using the following formula:

Equation 5. Tensile Index

Tensile Index (Nm/g) = 1,000 × Tensile Strength (kN/m) ÷ Grammage ( g/m 2 )

Instrumentation in the Graphic Arts Copyright © by Richard Adams is licensed under a Creative Commons Attribution 4.0 International License, except where otherwise noted.